„We provide you with the certainty you need for your daily material requirements“

© 2013 by Wagner-Tech-Textil GmbH · All Rights reserved · E-Mail: info@rexess.com · Designed by rexess.de

Thanks to its origin in the nature, the acetate yarn is endowed with similar properties as viscose and is pleasant to touch.

Exclusively from

Wagner-Tech-Textil GmbH

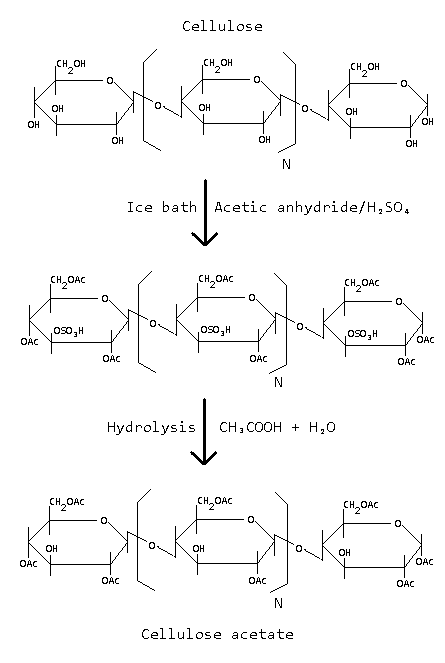

Cellulose acetate fibres are fibres from regenerated cellulose

, with at least 74% of hydroxyl groups being acetylated. They are produced through the process of acetylation of cellulose in a mixture of acetic anhydride (acetic acid and sulphuric acid). Then it is treated with a volatile solvent, acetone. Subsequently, the fibre mass is extruded through spinnerets. As the fibres emerge, the solvent evaporates in warm air. The resulting mixture contains between 49 and 54% of bound acetate acid and between 41 and 46% of cellulose, which is why the cellulose chemical fibre is said to represent a transition to a synthetic chemical fibre.Production of acetate (cellulose acetate)

The acetate yarn has a long and eventful history, which started before 1921.

Even though it was first produced as early as 1869, its commercial production began much later, after a suitable solvent was discovered. In the beginning, the acetate yarn was used for reinforcement of wings and fuselage in aircraft construction. After WWI, possibilities of using this new product in other areas were looked for. The use of cellulose acetate as a textile yarn was made possible after the discovery of a new class of disperse dyes in the early 1920s. Since then, the fibre technology has evolved considerably, while the original principle of acetate yarn production remained virtually unchanged.The beauty of the acetate yarn also consists in its ability to take on various forms.

The acetate yarn is ideal for fabrics that require excellent flowing effect. A big advantage of the acetate yarn lies in the fact that it can be easily mixed with other fibres. In combination with other fibres it is possible meet an even broader range of requirements. Blending with polyamide or polyester, for instance, enables to combine the strength of synthetic fibres with the beauty of the acetate yarns, thanks to which ultrafine fabrics such as crepe, Georgette and the finest tricot fabrics can be easily made. The acetate yarn has also affinity with natural fibres: the acetate yarn in warp and weft can increase the attractiveness of silk, cotton or wool, creating new and unexpected possibilities.The acetate yarn is made from natural materials

and abounds with qualities that are sought by consumers today. Comfortability to wear is in the first place. The customer who decided for the acetate yarn will be pleased because the acetate yarn lets skin breathe just like other natural fibres such as cotton or wool.Moreover, the acetate yarn is soft to skin and does not create static electricity.

These are important factors bearing in mind that today´s consumers are much more sensitive to the quality of clothing. The fabric’s aesthetic qualities are equally important and can mostly be attributed to the natural characteristics of the material. Thanks to the gloss of the fibre it is ideal for glittery and silky fabrics, ribbons and trimmings. When twisted, the fabric acquires interesting surface effects.The dye affinity of the acetate yarn is brilliant

. The fabric retains its colour, which is an important quality playing a significant role for the customer when choosing a piece of clothing. The acetate yarn is a versatile material with a broad range of possible use, including the fashion industry, household textiles as well as in medicine and many other areas. Acetate yarns are textile fibres made from the cellulose acetate. As in the production of viscose, the raw material here is cellulose. Textiles made of cellulose acetate fibre look very similar to natural silk and are almost as pleasant to touch. This is also why acetate yarn is known as artificial silk. They are usually crease-resistant and easy to care for. Water and swelling resistance makes the acetate yarn suitable for raincoat and umbrella fabrics. The glimmering appearance is nevertheless preserved. Furthermore, acetate yarns are used in the production of fabrics for blouses, shirts, dresses, lining, ties and lingerie.The origin and use of acetate yarns

Acetate yarn rexea®

Thanks to its origin in the nature,

The acetate yarn is attractive by its brilliant and natural appearance and silky and soft feel, regardless of whether it is high shine or matt.

Besides, the fibre is anti-static, which makes it comfortable to wear.

Our range of products is available on stock in 38 different colours, linear density 167 decitex (dtex), ready to be delivered immediately.

If you wish acetate yarns in 84 dtex, 110 dtex, 133 dtex or

330 dtex, it is possible to order the acetate yarn in the desired linear density.

the acetate yarn is endowed with similar properties as viscose and is pleasant to touch.

Exclusively from Wagner-Tech-Textil GmbH.The acetate yarn is attractive by its brilliant and natural appearance and silky and soft feel, regardless of whether it is high shine or matt.

Acetate yarn is yarn made from the renewable material of wood and is therefore environmentally friendly.

Besides, the fibre is anti-static, which makes it comfortable to wear.

Our range of products is available on stock in 38 different colours, linear density 167 decitex (dtex), ready to be delivered immediately.

If you wish acetate yarns in 84 dtex, 110 dtex, 133 dtex or

330 dtex, it is possible to order the acetate yarn in the desired linear density.

Synonyms: acetate | acetate yarn | acetate yarns | acetate fibre | cellulose acetate | acetate of cellulose | artificial silk | natural silk | textile yarns | chemical fibres | celulose acetate